Vretenborgsvägen 28, floor 6

SE – 126 30 Hägersten

Phone: + 46 8 683 03 00

Midstranda 51

NO – 2321 Hamar

Phone: + 47 62 54 02 91

Hassellunden 14

DK – 2765 Smørum

Phone + 45 70 300 310

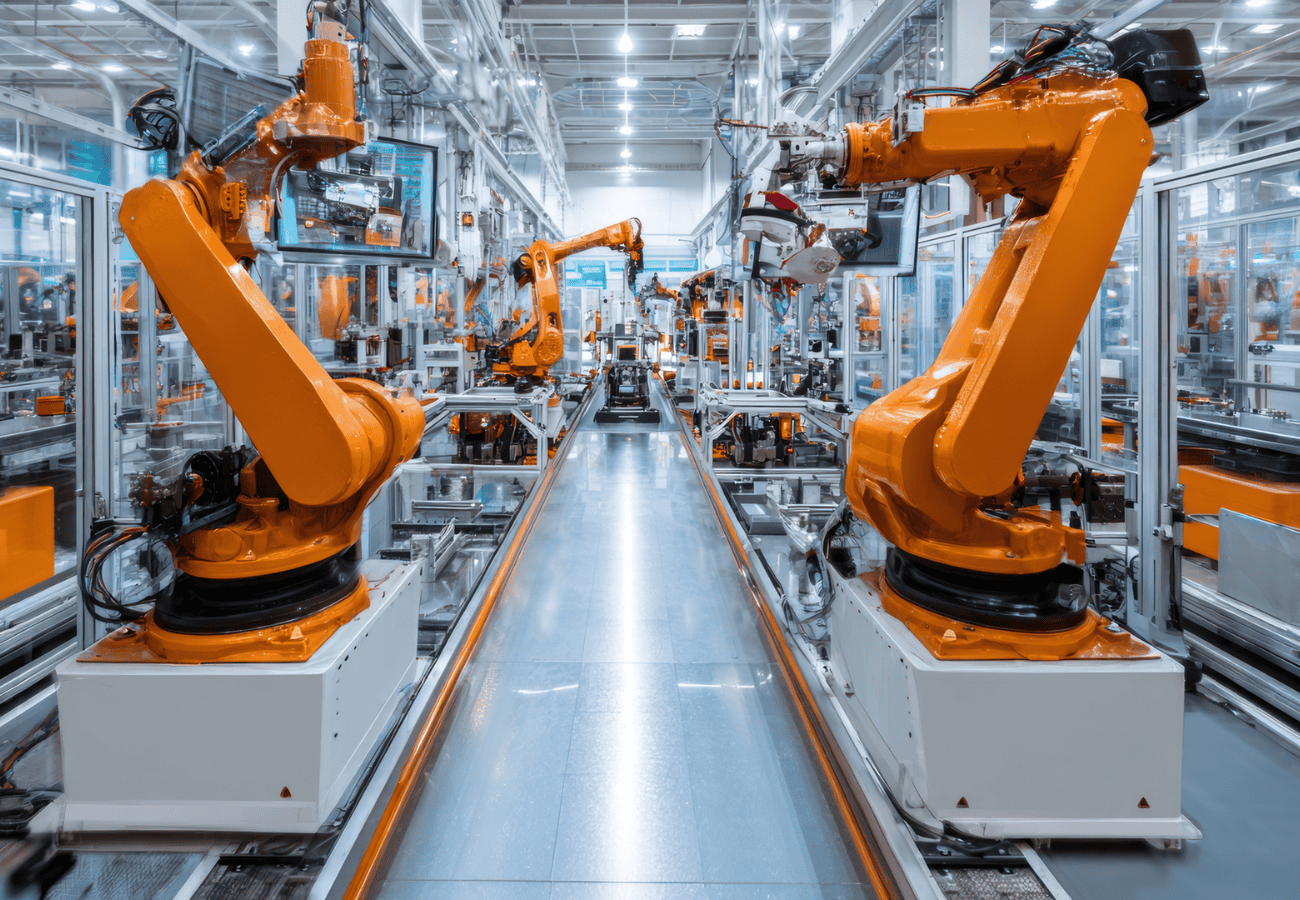

Machine automation demands high-performance computing and networking solutions engineered for industrial and factory environments. Recab delivers rugged platforms that ensure precision, uptime, and reliability — from real-time communication and AI-powered analytics to long lifecycle support in the most demanding production settings.

Recab delivers high-performance computing and networking systems built to sustain 24/7 workloads, wide temperature ranges and mission-critical uptime requirements. Recabs portfolio includes embedded industrial computers, rugged Panel PCs, real-time communication gateways, and AI-powered systems for machine vision and analytics. Each product is designed for integration into factory networks and adheres to leading international standards for safety, EMC compliance and industrial reliability.

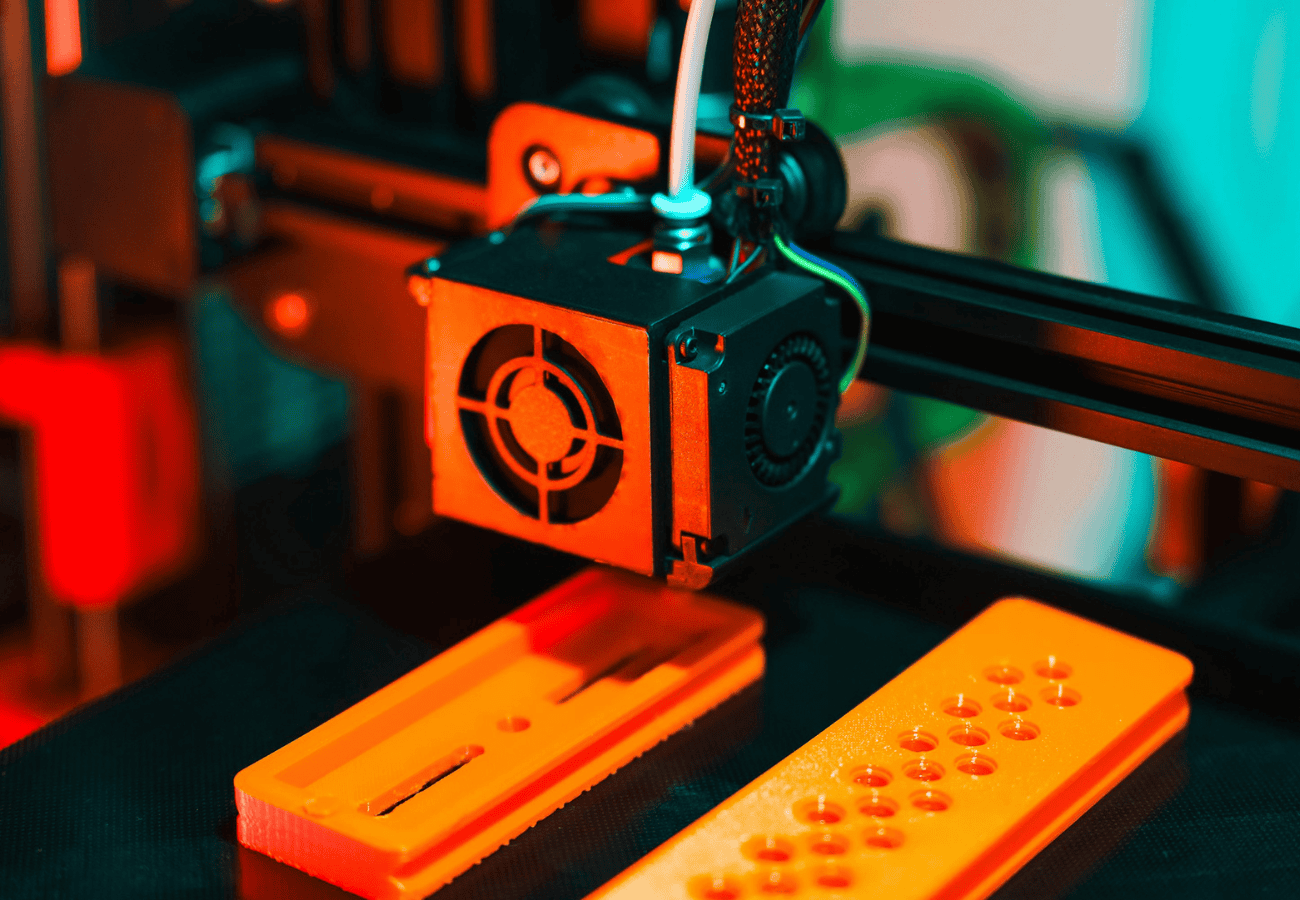

Industrial automation demands robust and precise computing solutions. Equipment must operate reliably on factory floors, in production lines, and within harsh industrial environments where dust, oil mist, vibration and electrical noise are constant challenges.

Recab solutions combine real-time data processing, cybersecurity, and modular design to ensure consistent performance, long lifecycle support, and easy maintenance, even in the most demanding production environments.

Let’s break down the most common standards and requirements for the machine automation market, highlighting safety and EMC compliance, real time communication and cybersecurity, edge performance, and long term reliability in demanding industrial environments.

Safety standard for information technology and industrial control equipment, ensuring electrical and mechanical protection.

Defines EMC emission limits for IT and multimedia equipment used in industrial automation.

Specifies immunity requirements protecting equipment from electrostatic discharge, surges, and conducted interference.

Comprehensive EMC immunity standards addressing surges, ESD, conducted and radiated disturbances.

Ensures dust and liquid protection suitable for oil-rich or washdown environments on the factory floor.

Designed for 10+ years of operation with long-term spare parts availability, software compatibility and modular integration in industrial cabinets.

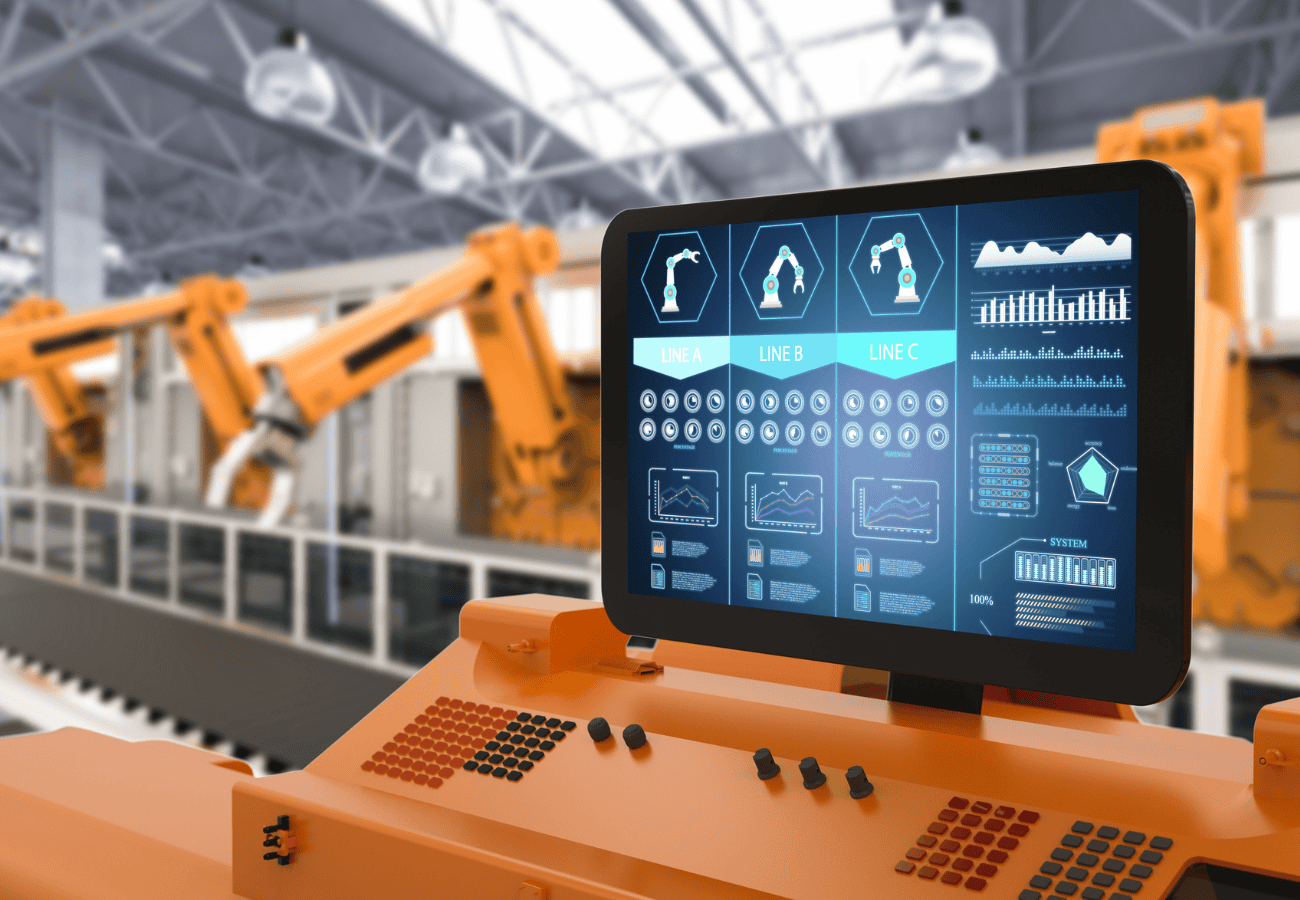

Supports real-time communication protocols such as PROFINET, EtherCAT, EtherNet/IP and Modbus TCP. TSN-enabled networking ensures deterministic, low-latency data exchange.

Integrated security functions including access control, encryption and role-based management, combined with network redundancy to minimize downtime and fulfill CRA requirements.

AI-enabled GPUs and accelerators support machine vision, predictive maintenance, robotic guidance and real-time analytics for intelligent automation.

Rugged displays and Panel PCs with glove-friendly touch, sunlight readability and extended temperature range operation.

From embedded industrial computers and rugged Panel PCs to real-time communication gateways and AI-enabled systems, Recab provides reliable solutions for factory automation and industrial control. Explore some of our key offerings designed to deliver precision, uptime, and long-term performance in demanding production environments.

Whether you have a project inquiry, need technical support, or want to explore collaboration, our team is here to help.