Vretenborgsvägen 28, floor 6

SE – 126 30 Hägersten

Phone: + 46 8 683 03 00

Midstranda 51

NO – 2321 Hamar

Phone: + 47 62 54 02 91

Hassellunden 14

DK – 2765 Smørum

Phone + 45 70 300 310

From configured off-the-shelf platforms to full custom design, Recab delivers precise system integration, qualification to industry standards, and long-term lifecycle management. We ensure your solution meets the demands of mission-critical environments while staying aligned with your budget and timeline.

From configured off-the-shelf to full custom, we design, integrate and qualify systems for harsh environments. We align hardware, software and partners to your standards and schedule—and support you through lifecycle and obsolescence.

Adapt proven platforms to your specifications for fast and low-risk delivery. We fine-tune firmware, apply OS images, and manage documentation and logistics to provide a system that is ready to deploy from day one.

Talk to our experts

Developing embedded systems doesn’t always have to start from scratch. At Recab, we specialize in Custom Off-The-Shelf (COTS) solutions – adapting and combining proven standard products to meet specific technical, environmental, and regulatory requirements. This approach offers the best of both worlds: the reliability of mature, field-tested platforms and the flexibility of a tailored design.

By modifying configurations, adding functionality, or integrating complementary modules, we can create a solution that perfectly fits your application – without the cost and lead time of a full custom development. Whether it’s adapting rugged embedded computers for defense, integrating I/O expansion for industrial automation, or optimizing thermal design for transportation, our engineering team, together with our partners ensures every system is purpose-built and compliant.

Our close relationships with world-leading manufacturers allow us to navigate lifecycle management, compatibility, and certification challenges efficiently. The result: faster time-to-market, reduced risk, and long-term system reliability.

With Recab’s COTS-based customization, you get a solution that performs like a bespoke system, designed smarter, delivered faster, and built on trusted technology.

When off-the-shelf solutions are not enough, we engineer bespoke electronics and mechanics tailored to your environment, performance requirements, and lifecycle. From early co-design to prototyping and compliance, we deliver hardware that is built to last in mission-critical settings.

Talk to our experts

Most projects can be realized efficiently through tailored standard solutions. However, there are situations where even the most flexible Custom Off The Shelf approach reaches its limits. This is when a full custom design becomes the right choice, either because no existing platform can meet the technical or environmental demands, or because the application requires absolute control over every design and production aspect.

At Recab, we develop complete custom embedded systems for customers whose applications demand full design control and optimization beyond what standard solutions can offer. A fully custom design allows full optimization of performance,

power, size, and lifetime while ensuring seamless integration into the customer’s product or system.

Our dedicated team manages the entire process, from concept and design through project management, prototyping, and validation to final testing and certification. Every stage is handled in close cooperation with the customer to ensure functionality, performance, and long-term reliability.

Full custom is not about replacing COTS, but extending what is possible when standard solutions no longer suffice. It is the path for those who need more than flexibility – they need complete design ownership.

We assemble, wire, and validate complete systems so they arrive preconfigured, tested, and field-ready. From hardware to software, our integration process ensures that every system is optimized for performance, reliability, and deployment in demanding environments.

Talk to our experts

At Recab, integration means refining and preparing systems to meet specific customer needs. In our ESD-protected integration center in Sweden, our experienced technicians assemble, configure, and verify products before delivery. This can be to maintain local control, ensure quality, or achieve cost efficiency. Each system is handled with care and prepared to perform as intended when it reaches the customer.

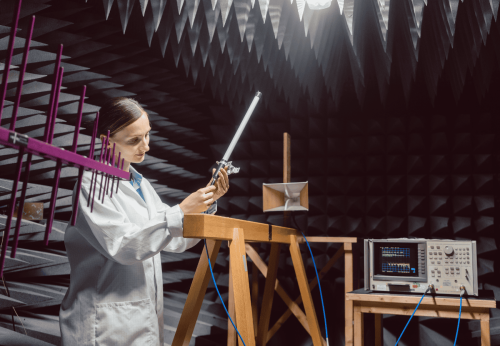

Every system is tested to the standards your industry requires, covering EMC, vibration, temperature, ingress, and more, with full documentation for compliance and certification. Our qualification services reduce risk, ensure reliability, and give you confidence that your solution is ready for deployment in critical environments.

Talk to our experts

Qualification is a key part of ensuring that every system meets both performance expectations and regulatory requirements. At Recab, we define what needs to be verified, manage the process, and make sure each system is tested according to the correct standards. Our engineers coordinate the full qualification flow together with both accredited and non-accredited partners to secure compliance of the products.

We secure long-term system availability through proactive lifecycle management — from change control and obsolescence monitoring to migration planning. Our approach ensures your mission-critical solutions remain reliable, maintainable, and up to date over decades of service.

Talk to our experts

At Recab, Product Lifecycle Management is about securing long-term product availability and minimizing risk throughout the entire system lifetime. We continuously monitor product change notifications (PCN), end-of-life (EOL), and not-recommended-for-new-design (NRND) alerts to ensure stability and predictability for our customers. By identifying potential lifecycle issues early, we help customers plan ahead, avoid disruptions, and maintain control over their designs and supply chain.